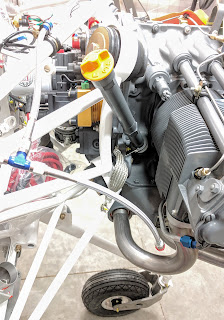

Engine Mounted ( 4 hrs )

Completed Sect 43-05 & -06 for fluid fittings, sensors on rear of engine. (did need to go to local store to purchase 13/16 deep socket, and 1" socket) Added the silicone hose to PMAG for the MAP connection. Mounted to firewall - carefully following instructions at 43-08 to insure "soft" vs "hard" durometer Dynafocal mounts were correctly positioned on top vs bottom (reversed). Contacted Vans tech support, and Eric Rushing confirmed the "

EA Dyna VI - Std" are the correct rubber mounts, even though Vans instructions call out different part numbers. Using the Harbor Freight engine hoist worked out really well. Eric mentioned typically builders need a couple helpers to wrangle the engine into the mount locations. I started with top 2 mounts, aud used hoist to re-position engine until bottom mounts aligned. I don't need the sawhorse holding up aft fuselage -- plenty of noseweight ! I've been told engine needs to compress rubber mounts up to 2 months before aligning cowling,...so let the compression begin!

|

glad able to add fluid fittings prior to mounting

since some would be challenging to do after |