Cont'd installing WH00125 Right Common Fuselage Harness. Disappointed in Vans Prod Support response: apparently earlier version of RV14's do have an open panel adjacent to center tunnel - but it's been changed for unknown reason(s). Ultimately had to cut panel out & deburr edges. Then filed notches and opposite side of holes to enlarge approx 1/8" (measured holes w/ notches first, and not possible for connector to be angled through). Very challenging even with these tweaks, but finally passed connector through all 3 holes in ribs to joystick, including inserting snap bushings. Wow ! Vans missed design for assembly in this area... [Other option was to remove all 10 pins from connector, and re-assemble after passing wires only. I chose not to do that to avoid damage to micro Molex pins - prior experience shows that's a risky option. Plus I purchased a complete harness from Stein Air, professionally assembled ! ]

|

| created template, then used hole saw in corners. |

|

| deburred, ready to try... |

|

| success. 12 pin micro molex connector installed onto joystick. And... I have to do other side too. |

|

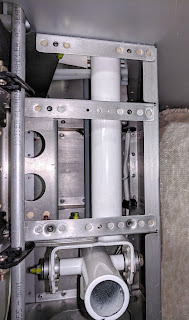

| top view. Even with opened panel, still awkward reach w/ minimal hand clearance. |

|

| Close up of inboard snap bushings, and next rib's snap bushing. Ground wire not yet attached to next outboard rib... |